Unitepcb is a leading manufacturer of HDI PCBs. HDI PCB is a thinner version of the traditional PCB board, making it lighter and more flexible. The company has been in business for many years, producing quality products and dedicated to customer service.

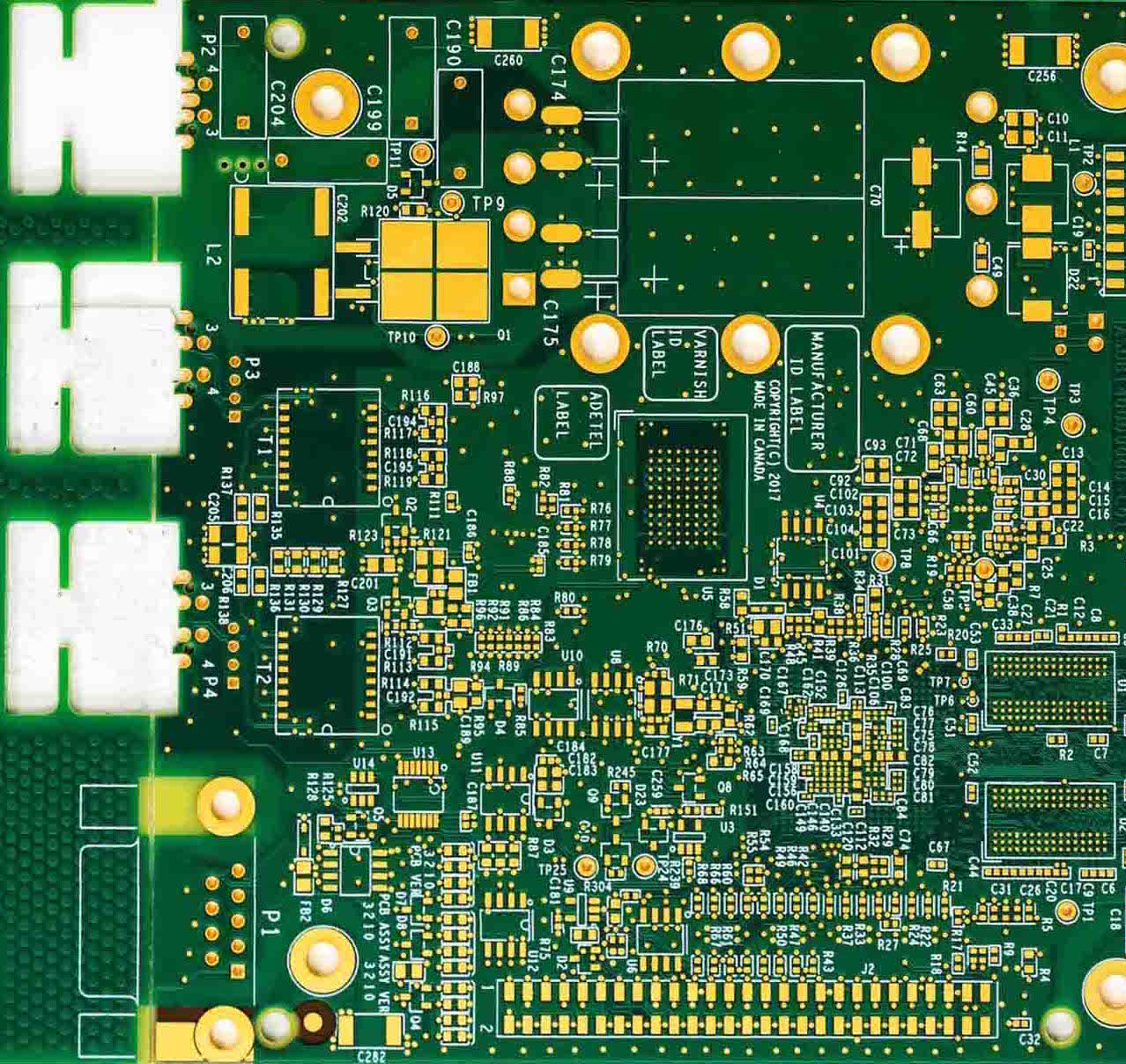

HDI PCB Manufacturing Process

The HDI PCB manufacturing process is a complex and precise process that requires great attention to detail. Unitepcb has years of experience in manufacturing HDI PCBs, and our team of experts are dedicated to ensuring that each board meets the highest standards of quality.

The first step in the HDI PCB manufacturing process is to create the circuit design. This is done by our team of engineers, who work closely with our customers to ensure that the design meets their specific needs. Once the design is complete, it is sent to our production team.

Our production team uses state-of-the-art equipment to fabricate the HDI PCBs. The boards are then subjected to a rigorous series of quality control tests before they are shipped out to our customers.

We are proud of our HDI PCB manufacturing process, and we are confident that our products will meet or exceed your expectations. If you have any questions about our process or products, please do not hesitate to contact us.

What is an HDI PCB?

An HDI PCB is a Printed Circuit Board with high density interconnections. It is designed to have more connections in a smaller area than a traditional PCB. This allows for higher data transfer rates and more efficient use of space.

HDI PCBs are made by etching thin copper tracks on both sides of a substrate. The tracks are then connected using vias (tiny holes). This process results in a very compact and efficient design.

HDI technology is often used in mobile devices, such as smartphones and tablets, where space is limited. It is also used in high-speed computing applications where data transfer rates are critical.

Unitepcb – A Leading HDI PCB Manufacturer offers a wide range of HDI PCBs for various applications. We use the latest technology to create highly efficient and reliable HDI PCBs that meet the demands of our customers.

Advantages of HDI PCBs

HDI PCBs offer a number of advantages over traditional PCBs, including:

- Increased circuit density: HDI PCBs can pack more circuits into a given space than traditional PCBs, making them ideal for use in compact electronic devices.

- Improved signal integrity: The higher circuit density of HDI PCBs results in shorter trace lengths and lower impedance, which leads to better signal integrity and improved performance.

- Lower weight and cost: HDI PCBs are typically lighter and less expensive than traditional PCBs, due to their smaller size and simpler manufacturing process.

- Increased reliability: The improved signal integrity of HDI PCBs often leads to increased reliability, as there are fewer opportunities for electrical problems to occur.

Recommendation for HDI Purchasers

As a leading HDI PCB manufacturer, Unitepcb has the experience and expertise to deliver high-quality HDI PCBs that meet the most demanding requirements. We offer a full range of HDI PCB services, from design and development to manufacturing and assembly.

Our team of engineers is highly experienced in working with HDI technology, and we have the latest equipment and facilities to ensure that your HDI PCBs are manufactured to the highest standards. We offer a wide range of materials and finishes to choose from, and we can work with you to create custom designs that meet your specific requirements.

If you are looking for a reliable HDI PCB manufacturer, Unitepcb is the perfect choice. We will work closely with you to ensure that your HDI PCBs are manufactured to your exact specifications, and we will deliver them on time and on budget. Contact us today to learn more about our HDI PCB services.