Did you know that the U.S. industrial metal coatings market size was valued at USD 15.0 billion in 2021?

But what are metal coatings, and how can they benefit your manufacturing processes? If you’re wondering how metal coatings can aid your manufacturing efforts, look here for the key facts.

Read on!

Anodizing

Anodizing is an electrochemical process that creates a protective oxide coating on metals and is often used to increase the wear resistance of aluminum or other metals.

It protects the metal by coating it and preventing rust.

Zinc

There are metal treatment methods that use in manufacturing for a variety of purposes. The most common type of metal coating is zinc. Aluminum, copper, steel, iron, and zinc can all be coated.

Zinc coatings come in a variety of forms, each with unique advantages. They offer defense against rust, wear, and the elements. They can also use them to improve the appearance of a metal surface.

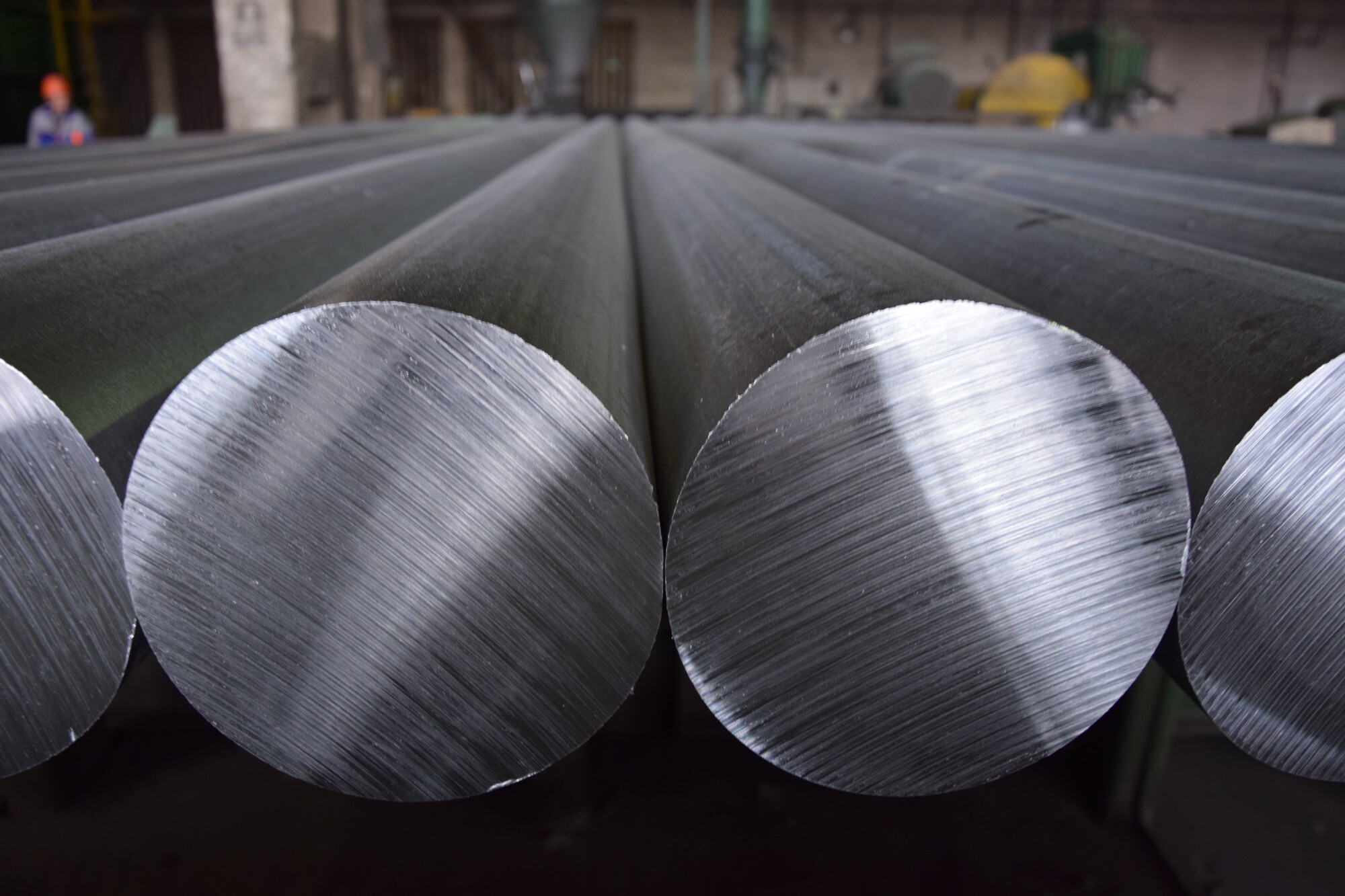

Aluminum

There are many types of metal coatings available in manufacturing. The most common type of coating is aluminum.

Aluminum alloys are used for corrosion resistance and to improve the appearance of the metal. It is also one of the lightweight metals to enhance performance and is corrosion resistant.

Nickel Plating

There are many purposes for metal coatings in manufacturing, and the type of coating used depends on the desired outcome.

For example, a harder coating, such as nickel plating, would be used if a high level of wear resistance is required. Nickel plating is also used to resist corrosion, as it creates a barrier between the metal and the environment.

Other coatings, such as gold plating, are used for aesthetic purposes or to provide electrical conductivity.

Copper

One of the most used metals in manufacturing, copper, has a variety of purposes and types of metal coatings available to suit those purposes. The three most common types of copper coatings are bare, tin-plated, and lead-free.

Raw copper is the most basic type of coating used for electrical applications where the metal needs to be soldered. Tin-plated copper is used more in manufacturing as it provides a more protective layer against corrosion.

Lead-free copper is the newest type of coating and is becoming more popular as the health risks of lead are more understood.

Chromium Plating

There are many different types and purposes of metal coatings available in manufacturing. One type of coating is chromium plating, often used to improve the appearance or durability of a metal object.

Chromium plating is a process in which a thin chromium layer applies to a metal object’s surface. This process improves the appearance of the thing by giving it a high-shine finish or protecting the object from corrosion or wear.

You can also use reliant finishing systems to help you with metal coatings.

Use Metal Coatings for Your Manufacturing Now

Metal coatings come in a wide variety of forms and use in Manufacturing. While others are for security, some are for aesthetics. Some layers apply to both goals.

The type of coating you choose will depend on the intended use. You can consult a coating specialist to find the best coating for your needs.

Did you find this article helpful? If so, you may check the rest of our site.

Read more articles at Ibomma News